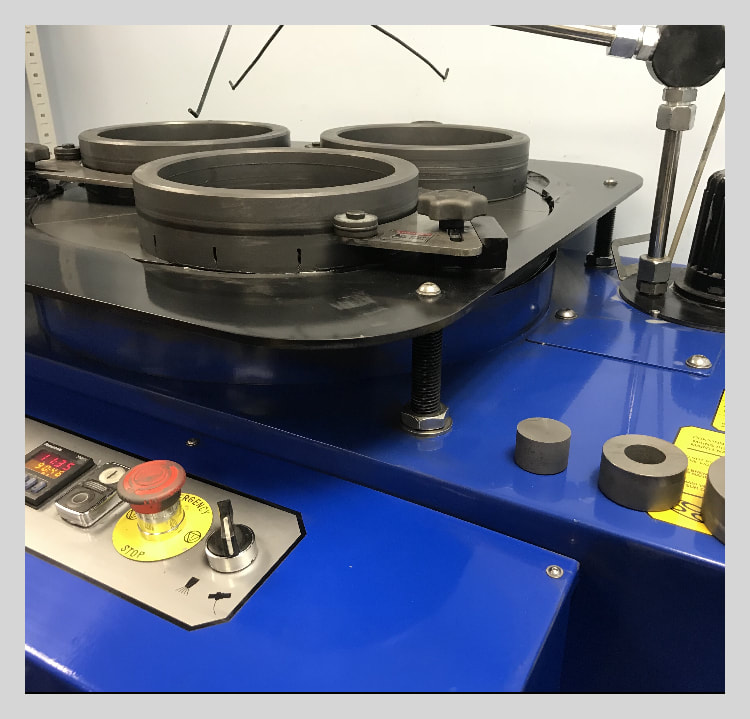

WORKSHOP CAPABILITIES

Our newly equipped workshop in the heart of the Teesside, has the capabilities and solutions to suit your engineering requirements for all related valves within the chemical, power, food and beverage industries.

Virasel Valve Solutions has the ability to offer valve maintenance services, whether the turnaround time is same day,or planning for shutdown requirements, our highly skilled team and testing facilities has the requirements to meet your demands on all sized manufactures of valves and models.

Once your valve arrives in our workshop it will receive a fully comprehensive overhaul:

Customer always informed of any spares of machining requirement needed to the valve, and recorded in photographic evidence.

Virasel Valve Solutions has the ability to offer valve maintenance services, whether the turnaround time is same day,or planning for shutdown requirements, our highly skilled team and testing facilities has the requirements to meet your demands on all sized manufactures of valves and models.

Once your valve arrives in our workshop it will receive a fully comprehensive overhaul:

- Pre-test.

- Dismantled

- Inspected

- All internal parts cleaned, degreased and measured.

- Seats and discs lapped and measured

- 2nd inspection after cleaning.

- Assembled (using OEM Spares)

- Tested, reset and calibrated in accordance with manufacturing standards.

- Test certification produced

- Paint finished if required.

- Valve wired and tagged.

- Engineers report produced showing photographic evidence of all internal and external parts.

Customer always informed of any spares of machining requirement needed to the valve, and recorded in photographic evidence.

"Communication is key from start to finish’’